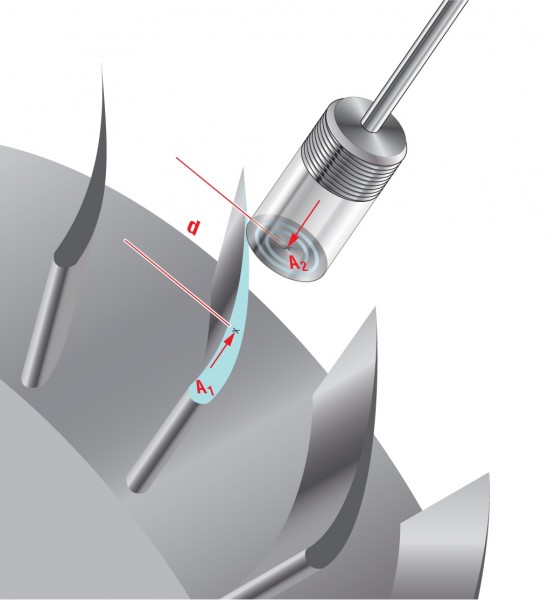

The GadCap CapaciSense system is non-contact measurement system that uses capacitance to detect the distance of an object and its time of arrival. This blade to sensor tip capacitance change forms part of a tuned oscillating circuit. The main factors which govern changes in sensor tip capacitance are the sensor/blade tip geometry and blade tip clearance. During operation the sensor/ blade tip geometry usually remains constant; therefore any changes in capacitance at the sensor tip are the direct result of variations in tip clearance.

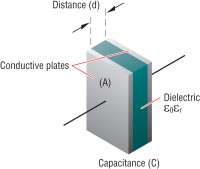

The core functionality of the system is uses capacitance parallel plate theory. The overlapping electrode area, which is specific to blade profile (A1) and electrode dimensions (A2), is assumed to be constant. The permittivity can also be considered to be constant as the small changes which do occur due to combustion, have been proved to be negligible.

The core functionality of the system is uses capacitance parallel plate theory. The overlapping electrode area, which is specific to blade profile (A1) and electrode dimensions (A2), is assumed to be constant. The permittivity can also be considered to be constant as the small changes which do occur due to combustion, have been proved to be negligible.

This theory gives us the ability to calculate the distance separating blade tip to sensor ‘plates’ by measuring the capacitance. The advanced electronics of the system convert this capacitance into a voltage, allowing a direct correlation between voltage and distance to be established while the blade is passing at over the speed of sound.

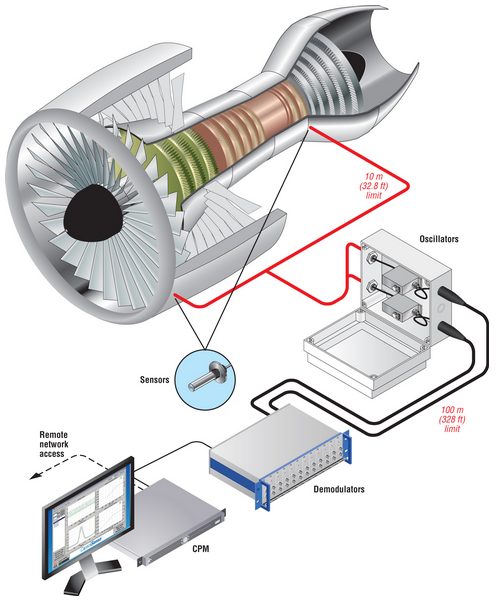

The affects of plasma charge in the turbine can influence the output from AM based systems hence the use of FM technology in turbine blade measurements. As the returned capacitance from a system such as this is extremely small (tens of femto farrads), advanced techniques need to be utilised to accurately measure them.

The affects of plasma charge in the turbine can influence the output from AM based systems hence the use of FM technology in turbine blade measurements. As the returned capacitance from a system such as this is extremely small (tens of femto farrads), advanced techniques need to be utilised to accurately measure them.

Where:

As C is proportional to 1/d, by measuring C, d can be determined.

Click on the parts of the system to see related product information.

5 Years! It’s hard to believe that it has been 5 years since the management buy-out that created GadCap Technical […]

Read more